Service Rates

Service Rates You Can Count On

Dependable, professional support at transparent pricing, whether it’s routine care or urgent repairs.

Standard Service

$ 175 .00

/ hour- Routine maintenance, repairs, and inspections

- 2-hour minimum per visit

- Trip charge based on service zone

After-Hours Service

$ 265 .00

/ hour- Scheduled maintenance or installs outside normal hours

- 2-hour minimum

- Trip charge applies

Emergency Service

$ 350 .00

/ hour- Priority dispatch for unplanned breakdowns

- 2-hour minimum

- Trip charge applies

Service Zones & Trip Charges

Trip charges vary by mileage from our Ontario, CA base.

Zones

- Zone 1 (1-5 miles) $30

- Zone 2 (6-10 miles) $40

- Zone 3 (11-20 miles) $50

- Zone 4 (21-30 miles) $65

- Zone 5 (31-40 miles) $80

- Zone 6 (41-50 miles) $95

- Zone 7 (51-60 miles) $110

- Zone 8 (61+ miles) $120/hr

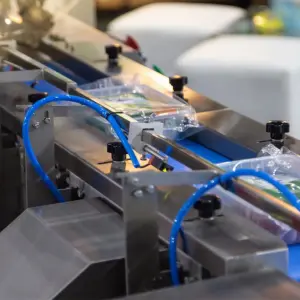

When Packaging Equipment Works, Everything Works

Reliability means fewer breakdowns, better output, and lower operating costs, giving your team confidence and your operation stability.

Efficiency

When equipment runs smoothly, your team can work faster and smarter. That means fewer bottlenecks and more product moved out the door.

Cutting Costs

Equipment failures cost money in wasted materials, repairs, and unplanned downtime. Proactive service helps reduce those surprises and keeps operating costs down.

Product Quality

Consistent packaging protects your products from damage, preserves brand reputation, and ensures every shipment arrives the way it should.

Reducing Waste

Well-tuned machines use materials optimally — less rework, fewer rejects, and less waste overall.

Meeting Safety Standards

Properly maintained packaging equipment is safer for operators and helps you stay in compliance with workplace safety guidelines.

How We Prioritize Preventive Maintenance

Unexpected breakdowns can grind your packaging line to a halt, slowing shipments and stressing your team. Preventive maintenance catches small issues before they become big problems.

How It Works

Our maintenance program is built to fit your schedule and volume:

Choose weekly, monthly, or quarterly check-ins that match your workflow.

You only pay when service happens — no subscriptions or monthly charges.

Every technician leaves you a detailed service summary and expert recommendations.

We inspect belts, sensors, seals, electrical components, controls, and more, so your equipment runs efficiently.

The Benefits of Proactive Maintenance

When you stay ahead of problems instead of reacting to them, you get:

Minimized

Downtime

Keep your packaging lines moving

Longer

Equipment Life

Extend the return on your investment

Better Budgeting

& Planning

Fewer surprise repair bills

Documentation

for Decisions

Track performance and plan upgrades

Brands We Service

Trusted by the Industry's Leading Manufacturers.

Equipment We Service

We support the full range of packaging equipment that keeps your operations flowing, from the first wrap to the final pallet:

Bagging

Balers

Carton Erectors

Carton Sealers

Conveyors

Cushioning Systems

Flow Wrapper

Heat Tunnel

Labeling

Load Transfer Systems

Pallet Systems

Shrink Bundling

Shrink Sealers

Strapping System

Stretch Wrappers

Ready to Keep Your Packaging Line Moving?

Don’t wait for downtime to strike. Whether you need regular maintenance or emergency support, the experienced team at GWC is here to help.